Professional Manufacturer and Supplier

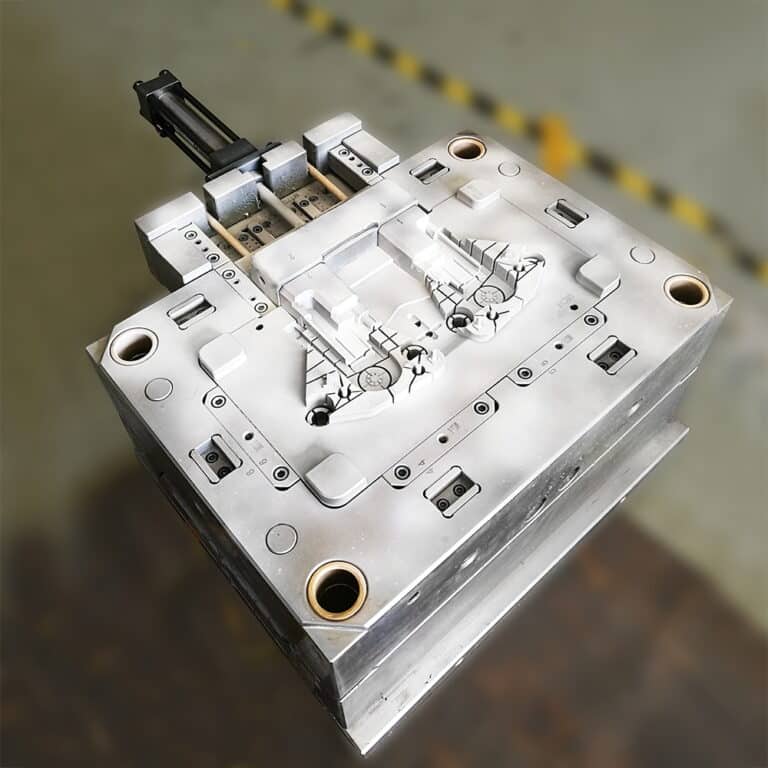

RCT MFG specializes in precision die casting mold design and manufacturing for aluminum, zinc, and other non-ferrous metals.

Our experienced engineers leverage the latest CAD/CAM and CNC machining to produce high-quality, durable molds optimized for your application. We offer complete mold design services including manufacturability analysis, simulation, and prototyping to ensure flawless mold performance. With advanced equipment and expertise, RCT MFG delivers complex, tight-tolerance die casting molds tailored to your specifications. Our molds enable quick, efficient production of premium die cast parts in large quantities.

Contact RCT MFG today to get started on your custom die casting mold project.

Expert in Die Casting Mould

RCT MFG is a certified Die Casting Mold Parts Manufacturer and Supplier. We are capable of providing our customers with various designs of Die Casting Mold Parts. RCT MFG guarantees that we can provide you with the highest quality parts to suit your needs.

As a professional manufacturer, we ensure that we have advanced manufacturing technology. So, you can be assured that we can provide you with different designs of Die Casting Mold Parts as per your requirements.

All our Die Casting Mold Parts are widely used in different industries and applications. They are very useful in the fields of automotive, medical, machinery, aerospace, plumbing, electrical, etc. RCT MFG provides excellent solutions for your applications.

We also customize Die Casting Mold Parts as per your specifications. We manufacture different types of Die Casting Mold Parts in different sizes, dimensions, shapes and styles as per your specifications.

We can also add your logo to your order to promote your brand. Just send us your details and we can provide you with a free quote.

RCT MFG also uses high-quality raw materials to manufacture Die Casting Mold Parts. It also uses various surface treatments like polishing, surface finish to ensure high quality. All products are manufactured with excellent quality at affordable prices.

We have more than 20 years of experience in this industry. So, you can be assured that we can provide solutions as per your needs. Our R&D team excels in prototyping, development and production of die casting mold parts.

Service Advantages

Contact RCT MFG for Die Casting Mold Production Services

Die Casting Mould Design Process

Designing a mold involves processes that come with multiple categories.

1. Preparation Phase: This is the phase where the validity of the product is evaluated from a dimensional and geometrical standpoint.

2. Cavity Numbers: Cavity orientation, product count, and hypothetical time cycle have to be considered for the cavity mold’s best option.

3. Projection Place: Projection has a significant role in the designing phase. It is also where the surface is created from the cavities plan.

4. Die Volume & Shape: Volume and shape are essential in mold design. Here, the cavities’ sizes can be molded accurately.

5. Simulation: This helps calculate the mold filling method. The modality depends on the filling process and process of the cast piece.

Die Casting Mould Advantages

Using die casting mold comes with multiple advantages, including but not limited to the following:

1. Achieves precise component shape configuration

2. Achieves dimensional accuracy

3. Quick production

4. Well formed thin walls than sand castings

5. A comprehensive range of requested shapes

6. Casting external threads capability

7. Overmolding steel insert possibilities

8. Holes can be centered on the interior tap drill dimension

The right choice of toolmaking

Because the right mold determines the quality of your product, the responsibility for the quality of your product lies with the mold manufacturer. The biggest challenges in moldmaking are to avoid unsightly dents in the material and to ensure a watertight seal. We have decades of expertise in the manufacture of molds for plastic injection molding and aluminum die casting. Thanks to global tool sourcing and our own tool maintenance and repair department, we can guarantee the required quality at a reasonable price. Our engineers provide support as early as the part design phase to ensure the best results and avoid unnecessary cycles. Depending on the requirements of the part, the delivery time and the required quantity, you can choose between aluminum tools or steel tools, the so-called "soft tools or hard tools".

Interested in working together on your new mold?

Reach out to our team for a quote. We’ll get back to you within 24 hours with options, pricing, and probably some additional questions about your application.