Polylactic acid, also known as polylactide, belongs to the polyester family. Polylactic acid (PLA) is a polymer polymerized with lactic acid as the main raw material. The raw materials are abundant and can be regenerated. The production process of polylactic acid is pollution-free, and the product can be biodegradable, realizing the circulation in nature, so it is an ideal green polymer material. Polylactic acid (PLA) is a new type of biodegradable material. It is made from starch materials extracted from renewable plant resources (such as corn) through fermentation, and then converted into polylactic acid through polymer synthesis.

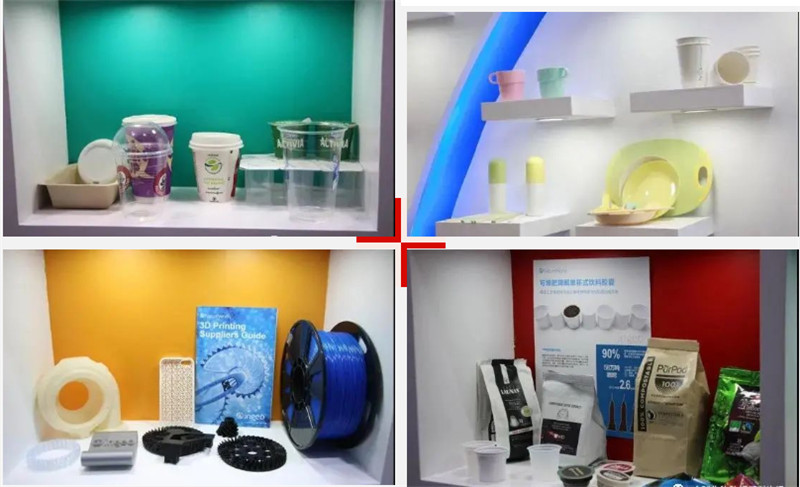

Polylactic acid is suitable for blow molding, injection molding and other processing methods. It is easy to process and widely used. It can be used to process various food containers, packaged food, fast food lunch boxes, non-woven fabrics, industrial and civilian fabrics from industry to civilian use. And then it can be processed into agricultural fabrics, health care fabrics, dusters, sanitary products, outdoor UV resistant fabrics, tent fabrics, floor mats, etc. The market prospect is very promising. It can be seen that its mechanical and physical properties are good.

What are the advantages of raw material PLA?

1. It has good biodegradability. After use, it can be completely degraded by microorganisms in the nature under specific conditions, and finally generate carbon dioxide and water, without polluting the environment. The treatment method of ordinary plastics is still burning and cremation, which causes a large amount of greenhouse gases to be discharged into the air, while polylactic acid (PLA) plastics are buried in the soil for degradation, and the carbon dioxide generated directly enters the soil organic matter or is absorbed by plants, which will not be discharged into the air and will not create a greenhouse effect.

2. Good mechanical and physical properties. It is easy to process, widely used, and has a very good market prospect.

3. Good compatibility and degradability. It is also widely used in the medical field.

4. Polylactic acid (PLA) is similar to petrochemical synthetic plastics in basic physical properties and can be widely used to manufacture various application products. Poly (lactic acid) (PLA) also has good luster and transparency, which is equivalent to the film made of polystyrene and cannot be provided by other biodegradable products.

5. Polylactic acid (PLA) has the best tensile strength and ductility, and can also be produced by various common processing methods. Poly lactic acid (PLA) can be made into various products according to the needs of different industries.

6. Poly (lactic acid) (PLA) film has good air permeability, oxygen permeability and carbon dioxide permeability, and it also has the characteristics of odor isolation. Viruses and molds are easy to attach to the surface of biodegradable plastics, so there are doubts about safety and hygiene. However, polylactic acid is the only biodegradable plastics with excellent antibacterial and anti mold properties.

7. When PLA is incinerated, its combustion heat value is the same as that of paper, which is half of that of traditional plastics (such as polyethylene). In addition, it will never release nitrogen compounds, sulfide and other toxic gases.

Post time: Apr-11-2023