Custom Mold Manufacturing

Need mold making supplies for mass production of parts? RCT MFG is known as the best mold maker in China. With in-house mold making facilities and the resources of our partners, we are able to provide plastic injection molds for hard plastics and rubber, metal injection molds for all types of precision stainless steel parts, and die casting molds for aluminum, magnesium, and zinc. We offer low-cost local production molds and high-quality export molds for all your project needs. Our team has years of combined experience in a variety of molding technologies, allowing us to create molds that meet your unique requirements and specifications. In addition, we work closely with you to create results that meet your expectations, thereby helping our customers succeed.

About RCT MFG’s Custom Mold Manufacturing Process

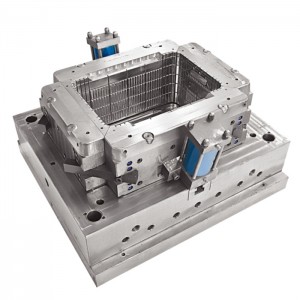

At RCT MFG, the entire custom mold manufacturing process is a collaborative effort, from design to production preparation. How the mold is designed, built, and tested determines the foundational strength of the entire manufacturing process.

RCT MFG also offers the ultimate in flexibility because we utilize mold manufacturing facilities. With the broad capabilities in our talent pool, we match each job with the right skill set for each mold design, no matter how simple or complex. Each mold undergoes a final inspection at RCT MFG’s facility.

There always seems to be a few challenging component designs for nearly every product. However, it’s those one or two challenging components that make the difference between a mediocre product and an excellent one—whether the finished product is consistently satisfying, both in terms of functionality and manufacturability.

Capabilities

1. Quotes in 48 hours

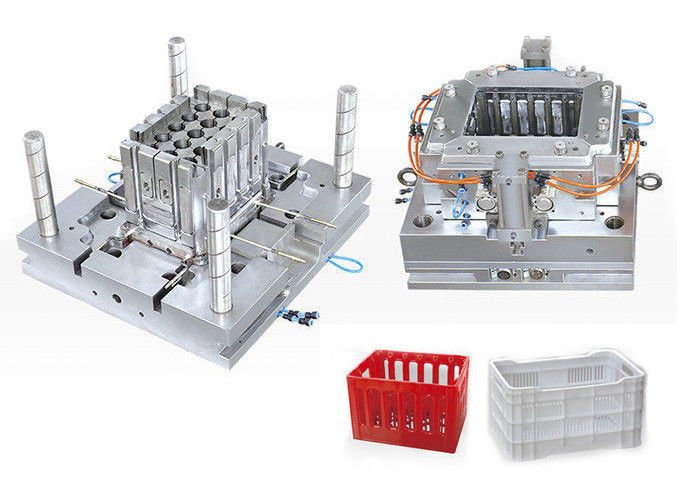

2. Multi-cavity mold design

3. Our team provides free guidance during the molding process.

4. Insert molding

5. Overmolding

6. Low volume production parts

7. Tight tolerance

8. Custom colors

9. Complex and large parts

10. Sample parts

11. ISO 9001 & BSCI

12. Presses ranging from 80 to 1100 ton

Types of Molds We are Offering

Plastic Injection Molds

Export Injection Molds

Rapid Tooling

Die Casting Injection Molds

Custom Molds Made from Reliable Materials

We utilize different metals to create the right custom molds. For instance, rotational, compression, and injection molding techniques require molds made from metal or epoxy. These are expensive but are very durable, especially in full production runs.

Two common materials used in custom mold making:

1. Steel: Steel materials are wear-resistant and withstand high pressures, making them durable and ideal for long-term use. It also offers maximum strength for high-volume processes.

2. Aluminum: Cheaper than steel, aluminum is an excellent option for those looking for an alternative with the same quality as steel. It's lightweight and has incredible workability, which allows for more design flexibility.

Choose Advanced Prototyping Technology to Achieve the Custom Mold You Want

RCT MFG also offers prototyping and testing of custom molds prior to the manufacturing stage to ensure they match the characteristics you are looking for. These are also ideal for situations where durability is not an issue. It is best to start here and then move on to more durable options.

If you have any questions or concerns about our products and services, please contact us today. You can also request a quote and we will send some estimates for your project. Contact us today and we can find solutions for your different production problems.

Start Your Project With A Free Quote

Get in touch with a project manager and take the next step with your prototyping or manufacturing needs.