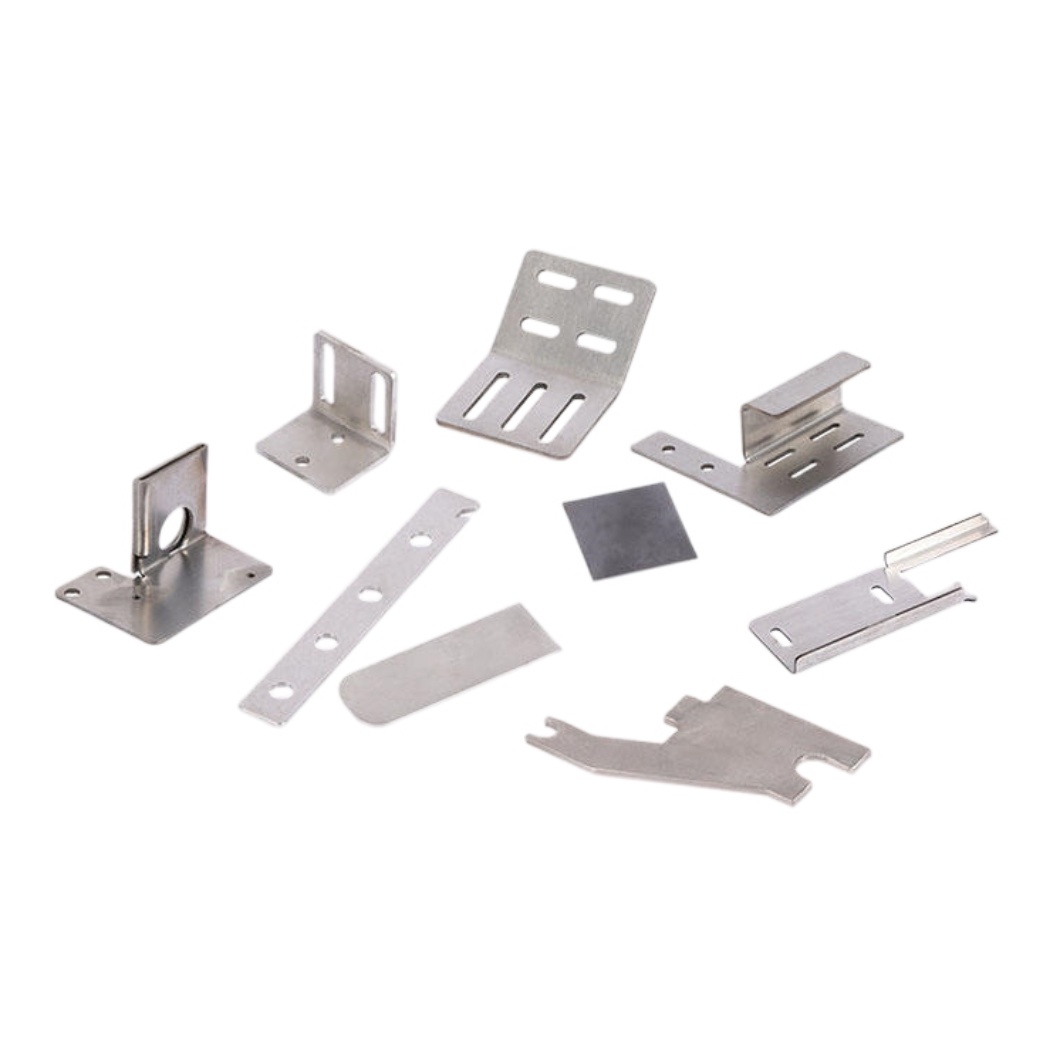

High volume metal stamping capabilities for virtually any product

Our in-house engineering department provides customers with a turnkey solution including design development, rapid prototyping, production and custom automated assembly machinery. All of our dies and tools are engineered in-house to maintain tight tolerances from a wide range of alloys in a variety of configurations from 0.008” to 0.070” thick with tolerances to +0.002.”

With a state-of-the-art EDM and CNC machines, our expert die makers make high quality tools. We work closely with our customers to ensure the most cost-effective material, plating, and packaging is selected for their product needs. Our facilities have over 20 high-speed stamping presses ranging from 10 to 60 tons that operate nearly 24 hours a day. We service over 1,000 customers throughout the world, providing a range of custom stampings from reel-to-reel terminals to complex large loose piece automotive lead frames.

The RCT MFG Advantage

We specialize in short-run and medium-run metal stamping – but what makes us different? The advantage to partnering with RCT MFG speaks for itself:

1. Part-to-part & Order-to-Order repeatability

2. In-house equipment standardization

3. Tighter tolerances than fabrication

4. Ability to react quickly to design changes

5. Lower part price than fabrication

6. Climate controlled factory

7. Lower tooling expenditure than progressive dies

8. Blanking presses to 150 tons

9. Precision stamping with laser cutting

10. Automatic feeding system to bend and punch metal in a shorter amount of time

Precision Metal Stamping Capabilities

1. Progressive Die Stamping with:

In Die Tapping and Threaded Inserts

In Die Assembly

In Die Roll Forming with Dovetail Interlocked

2. Progressive Deep Drawing

3. Transfer Deep Drawing

4. Transfer Stamping / Forming on Extruded & Pre-Machined Tube

5. Reel to Reel Stamping

RCT MFG’s stamping processes employ top-of-the-line precision metal stamping presses (robotic, manual, or progressive lines) including Minster, Sutherland, Chin Fong, Aomate, Micron, Kamatsu, Yamada Dobby, PATEC, SEYI, V&O, and AIDA. At RCT MFG, punch presses range from 25 tons to 500 tons, and CNC equipment is used in conjunction with special universal units, holders & fixtures to manufacture custom metal stampings. Parts of any shape can be blanked, pierced, formed, stenciled, drawn, and extruded.

These services are supported by a wide range of secondary process capabilities including mechanical assembly, staking, tapping and welding, deburring, degreasing, and various packaging options.

Stamping, Die Design and Fabrication

RCT MFG has a strong in-house tool manufacturing capability to ensure our stamping tools exceed our customers’ requirements. With decades of tool design expertise, RCT MFG is able to provide innovative solutions to our customers’ stamped metal needs, integrating transfer stamping and multi-stage progressive tooling with in-die joining and assembly processes into the metal stamping process. These can help reduce costs depending on the application.

Our state-of-the-art tool designs utilize the highest quality CAD packages including Cadkey and AutoCAD, as well as 3D CAD packages including SolidWorks and Pro E.

All of our manufacturing facilities are equipped with in-house rapid tool prototyping and fabrication capabilities, and are equipped with full tool room machinery, resulting in fast turnaround times.

Ready to start your metal stamping project?

A Variety of Metal Stamping Options

The type of metal stamping that's best for you will depend on your production goals and requirements. Production volume, uniformity needs, and component complexity will all influence which metal stamping is the most effective choice.

1. Progressive Die Stamping: Also known as progressive stamping, this process passes a strip of metal through a series of progressive stamping stations. Each station performs a specific function (such as bending, punching, or other functions) to produce complex parts. It's a fast, repeatable process that produces uniform components.

2. Multi-slide and Four-slide Stamping: Multi-slide metal stamping, also known as four-slide metal stamping, is a precision option for making complex parts. While it doesn't produce a completely consistent final part, it's an excellent choice for orders that require design flexibility and versatility.

3. Deep Drawing: Deep drawing uses a punch to feed the blank into a die and is an ideal metal stamping process for products that require extremely deep shapes. Deep draw metal stamping has low material waste and is ideal for low-volume production of simple parts.

Metal Stamping Processes

Custom metal stamping is completed with stamping dies typically manufactured from tool steel, which is hard enough to cut most other types of metal while maintaining your required tolerances. Various kinds of metal stamping techniques are used to create your desired result, and your best process may include:

1. Blanking: Blanking removes a workpiece from the original metal to create your designated form. It is the opposite of punching as the removed metal becomes the shape or blank.

2. Punching: Punching uses a die and a punch to cut sheet metal into your designated shape. Excess material is dispelled from the surface, and the remaining form creates your final part.

3. Bending: Metal sheet is bent and formed to match your shape specifications. The most common forms are L, U, or V-shapes as this process is accomplished by bending a material around a single axis.

4. Drawing: Using a compressive force, sheet metal is formed into a cavity or around the desired shape. Drawing is also sometimes referred to as forming.

5. Embossing: Embossing uses a die to apply a shape onto metal material, imprinting the pattern or design onto the workpiece.

Custom Metal Stamping For Any Material

RCT MFG’s state-of-the-art facility allows us to provide precision metal stamping manufacturing with various kinds of metal, including:

1. Stainless Steel

2. Aluminum

3. Cold Rolled Steel

4. Hot Rolled Steel

5. Pre-Galvanized Steel

6. Annealed Steel

7. Brass

8. Copper

9. Plastic

Industrial Applications of Metal Stamping

Common applications include:

1. Automotive Stampings

2. Building Products

3. Solar BOS (balance of system) Components

4. LED Lighting

5. Electric vehicle EV Components

6. Roofing Products

Quality Systems

All our facilities are ISO 9001 certified. In addition, RCT MFG has experience in many industry and application-specific quality control systems and processes.

1. Production Part Approval Process

2. Control Plans

3. Failure Mode & Effects Analysis (FMEA)

4. Measurement Systems Analysis (MSA)

5. Initial Process Studies

6. Statistical Process Control (SPC)

Our quality labs also have established calibration systems for everything from CMM and optical comparators to hardness testing.

Contact our team of experts today

RCT MFG is a reliable supplier of precision metal stampings. Request a quote for custom stamped metal parts, or contact us to find out what we can do for you