Let Us Handle Your Sheet Metal Bending Project

If you are looking for an experienced team to execute your metal bending project, you can trust RCT MFG! We love helping our customers benefit from our solid expertise in custom bending, steel bending, aluminum bending, PVC bending, and sheet metal bending. Our expertise is backed by state-of-the-art equipment in our workshop, allowing us to execute your most ambitious projects.

At RCT MFG, we offer a range of metal bending services to meet the needs of our customers. Our state-of-the-art equipment and experienced technicians ensure that each project is completed to the highest standards of quality and accuracy. In addition, we can also provide custom fabrication services to create unique metal structures that meet the specific needs of your project.

Various Sheet Metal Bending Techniques

Various Angle

Bending at different angles, such as rounded angle bending, acute angle bending, obtuse angle bending

Various Shape

Bending metal sheets into different shapes, such as V-shapes, is often used to make boxes, and other containers.

Air bending

The bending force and speed are precisely controlled to avoid leaving traces of bending.

Multi-step Bending

Multiple steps and different bend directions may be required to achieve the desired shape for complex parts.

Crafting Excellence through Sheet Metal Bending Services

RCT MFG expertly fabricates precision bent components ideal for use in surgical devices, heat exchangers, instrumentation, handling equipment, diagnostic equipment and more. RCT MFG is a specialist for precision metal bending services and coiling of stainless steel, copper, aluminum and other materials. All custom bent components are offered in sizes ranging from .032″ to 1″ diameters, as well as numerous wall thicknesses, with minimal radius and wall thinning requirements.

Small diameter stainless steel tubing can be bent to specific shapes and angles using specialized bending equipment and techniques. RCT MFG ensures that the bending process adheres to proper procedures and industry standards to avoid kinking, wrinkling, or compromising the material’s corrosion resistance and structural integrity. Factors such as the tubing’s alloy, wall thickness, and bend radius are carefully considered to achieve successful and reliable bends.

Request a free no-obligation quote

What is metal bending?

Metal bending is a process of deforming metal by applying a force to the object. The bending is done at an angle and gives it the intended shape, which is often a “V” or “U” shape.

There are several methods using one or more machines depending on the part to create and the shape to be obtained. Those most commonly used in sheet metal bending are the “press brake” and the “hydraulic press”. The difference between these 2 tools is that the hydraulic press works in two dimensions while the press brake only works in one.

How does Sheet Metal Bending work?

Sheet Metal bending is a standard metal forming process that involves manipulating metal sheets using various tools and machines. During the bending process, the sheet metal is often clamped between a punch and die and then pressed to create a bend at a specific angle. The amount of force needed to achieve the desired turn is determined by several factors, including the type of metal being used, the thickness of the sheet, and the bend angle.

Metal bending can be performed using various methods, including air bending, bottom bending, coining, roller bending, and v bending. Each technique offers unique advantages and is selected based on the project’s specifics. After bending, the sheet metal is often trimmed, and excess material is removed using various machining processes. Overall, bending sheet metal is a crucial process that creates durable, high-quality metal products for multiple industries and applications.

Materials

RCT MFG is a highly specialized company. We are experts in working with various materials, including aluminum, copper, stainless steel, and titanium. Aluminum, for instance, is known for its lightness and corrosion-resistant properties, making it a popular material in many applications. On the other hand, copper is highly conductive and heat-resistant, making it an excellent choice for electrical and industrial applications. Stainless steel is another popular material used for its durability and corrosion-resistant properties while providing a modern appearance. Lastly, titanium is a strong yet lightweight valuable material in extreme environments such as aerospace and medical applications. With its expertise in sheet metal bending and its knowledge of these materials, RCT MFG is well-equipped to handle any project and is heat-resistant, which makes it an excellent choice for electrical and industrial applications. Stainless steel is another popular material used for its durability and corrosion-resistant properties while providing a modern appearance. Lastly, titanium is a strong yet lightweight valuable material in extreme environments such as aerospace and medical applications. With their expertise in sheet metal bending and their knowledge of these materials, RCT MFG is well-equipped to handle any project.

Finishes

Choosing the right finish for sheet metal fabrication projects is crucial for looks and protection. Options include powder coating, painting, anodizing, and plating. Each has benefits and drawbacks, so select depending on the application, metal type, budget, and environment. Partnering with an experienced sheet metal fabrication company will guide the right choice of finish, enhancing appearance and increasing durability.

Our Custom Metal Bending Services For Various Industrial Applications

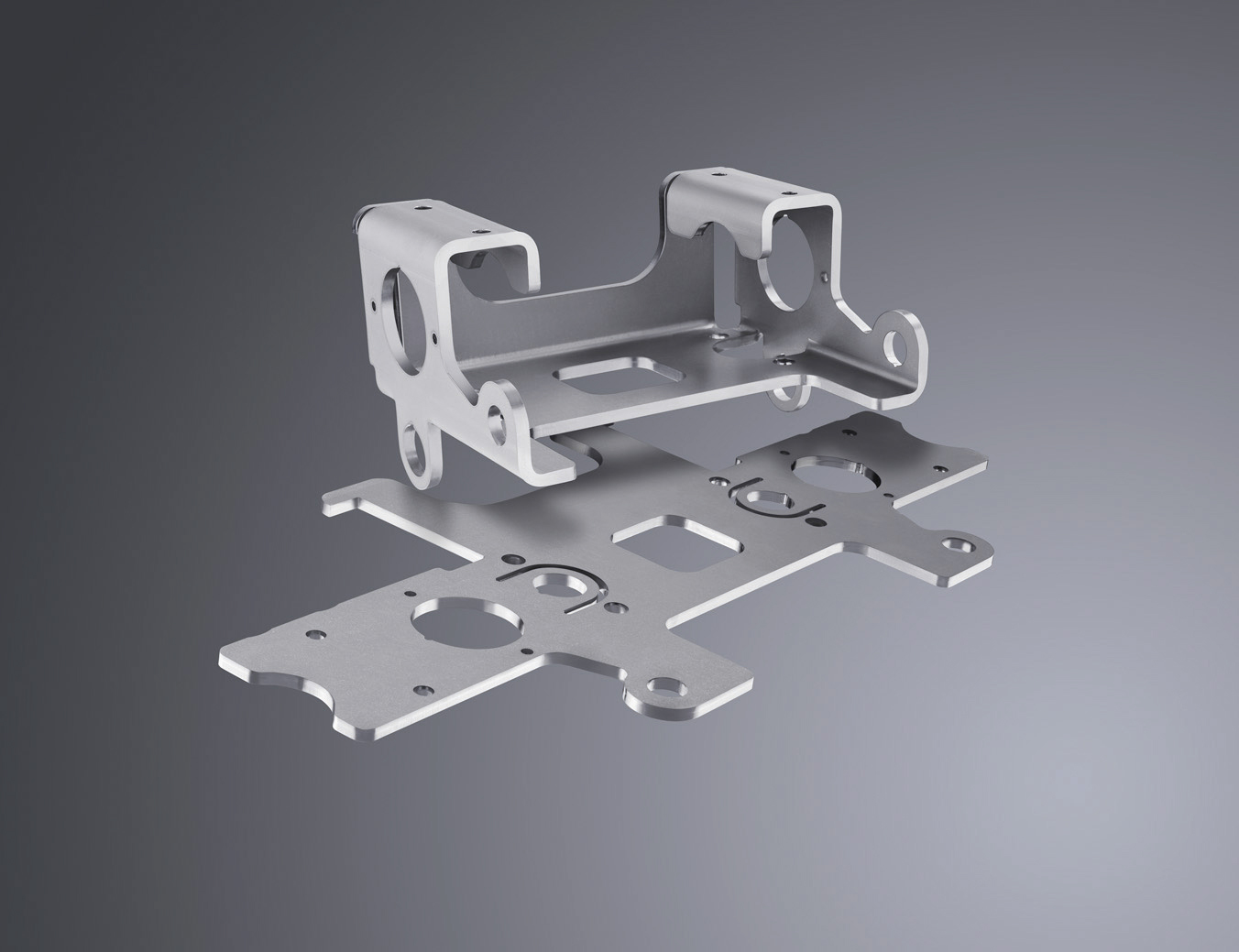

Our advanced equipments and skilled engineers allow us to offer high precision metal bending parts. Hope these delicate parts below will leave you a good impression about manufacturing industry.

1. Automotive

2. Construction

3. Contractors

4. Home Improvement

5. Hobbyists

6. Maintenance

7. Manufacturing

8. Military

9. Movie Production

11. Transportation

12. Tool & Die

13. Welding

14. And more

RCT MFG Performs Your Custom Machine Bending Project

As a company specializing in machine repair, we offer a wide range of fabrication services. Our expertise extends beyond metal bending, we also master all the processes behind industrial welding and precision industrial fabrication.

When you hire RCT MFG to handle your Montreal aluminum bending needs, your company will benefit from:

1. Highly accurate service at all times

2. A wide range of potential aluminum depths

3. Advanced equipment that can be adjusted to your needs

Our wide variety of machines, combined with the extensive experience of our operators, allows us to handle a wide range of industrial projects. RCT MFG can provide metal bending services to a wide range of industries.