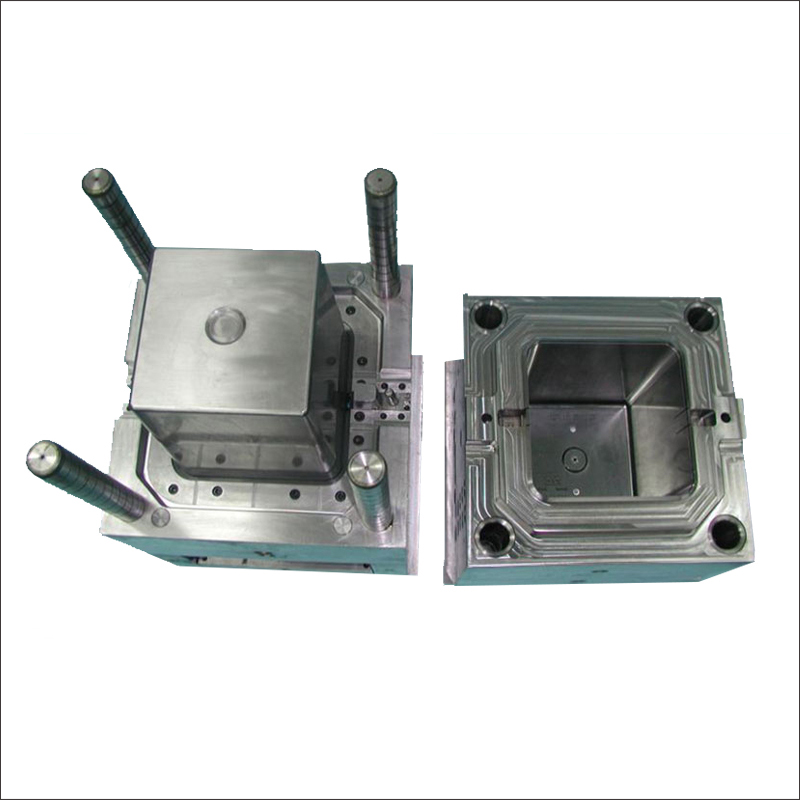

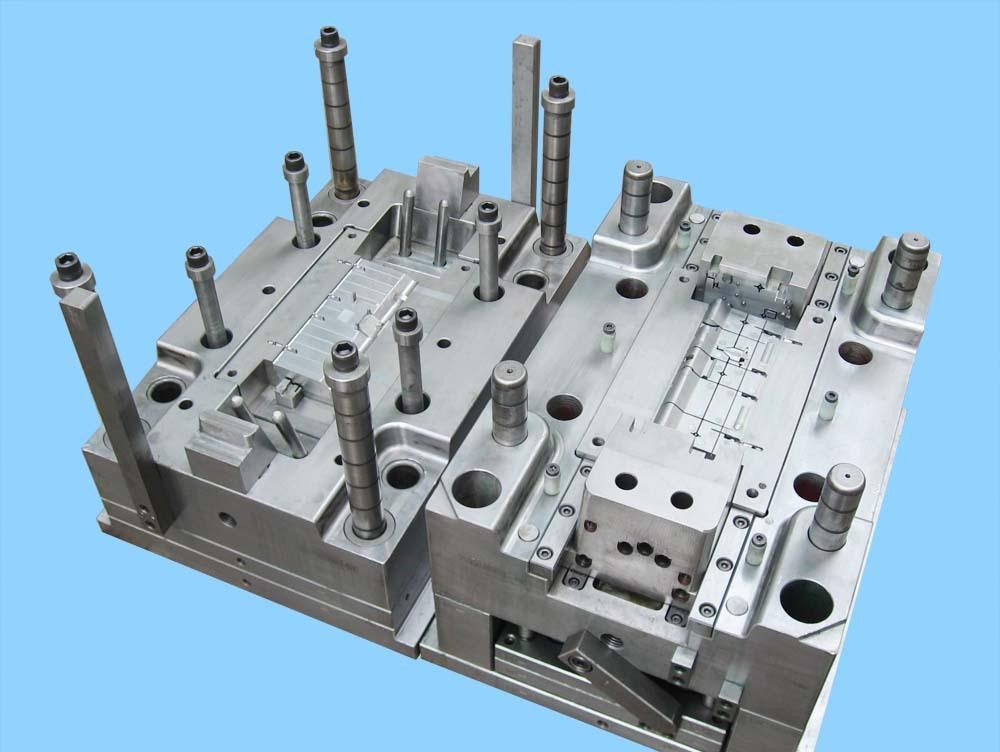

Custom Plastic Injection Mold Manufacturing Service In China

RCT MFG offers a full range of production injection molds that will be exported from our wholly owned manufacturing facility in China for you to run in your own facility or at your designated manufacturing facility. The plastic mold will be designed and manufactured to US/Western standards. It will be optimized for production on your injection molding machine and will come ready with details such as cooling line connections for your existing setup.

Contract Mold Manufacturing

RCT MFG provides production molds that can be delivered to the customer's facility or designated manufacturing location. We manufacture molds for nearly all major plastic end markets, such as household goods and precision medical parts, aerospace components, automotive components or micro parts for consumer electronics. All molds are manufactured to your specifications, including steel type, runner system, gate type, cavity material and other specified features. Once the mold arrives at your facility, it can be directly installed in your injection molding machine and put into production.

Our Service

| Mould Basic Information | ● Mould Base Material:HASCO, DME, RABUDIN, DIN, JIS, LKM. ● Mould Core Material:718, H13 S136,P20,NAK,LKM,EK4,X13T6W etc. ● Hot runner:Mold-masters,Master Tip,Husky,Hasco,DME,Yudo,Incoe,Thermoplay etc. ● Standard Parts:DME,HASCO,NEAREST ANSI STANDARD,NEAREST DIN STANDARD,LKM etc. ● Texture:Mold-tech,Nihong,Yich Sang,Yixin,Tanazawa. ● Mould Life: around 500000 to 1000000 shots |

| Mould Type | ● Hot runner Mould ● Multi-cavity mould ● Two-shot injection mould ● Insert Mould ● Custom Injection Mould |

| Mould Gate | ● Side Gate / Edge Gate ● Submarine Gate ● Pinpoint Gate ● Sprue Gate ● Tunnel Gate |

| Advantage at RCT MFG | ● Strong Technical Support: A technical R&D department with professional engineers, which can offer you with engineering and technical design support in mold and product design. ● Strict Quality Control System: As a ISO 9001:2008 certificated manufacturer, we will offer you the high quality products. ● Superior Service: The professional sales staffs would answer you in time, there is no communication problem. ● Stability and Reasonable Price & Speed Delivery Turnaround ,Mould delivery time is 15-45 days according to its structure and size. 7-20days for ● Mass production according to order quantity. |

What you need to know when buying plastic injection molds

RCT MFG offers complete plastic injection mold production, which will be exported from our wholly owned manufacturing facility in China for you to run in your own facility or at your designated manufacturing facility. The plastic mold will be designed and manufactured to US/Western standards. It will be optimized for production on your injection molding machine and ready for details such as cooling line connections for your existing setup. Typical steel types for these molds are 718/718H, S136/S136H, NK80 or customer requested steel types.

Different customers have different requirements for molds, so we can manufacture to your plastic mold injection molding system specifications, including steel, hot runner system, process, surface finish or texture of the injection mold plastic. We can also meet your functional requirements for molds and injection molding, and match production specifications and mold designs. Once the mold is completed, trial production and short-term production can be carried out, such as to fill gaps in production molds.

Quality is critical, and not all mold makers are created equal

Injection molds are a big investment, so it’s important to choose a mold maker that produces high-quality molds. You need to make sure your injection molds are up to spec, because even a little deviation can lead to problems like flash (material that seeps out where the two halves of the mold join) during the molding process. This will result in a lower quality finished part, and may require extra time to clean up the part. You must also consider the quality of the material when purchasing a mold. While aluminum molds are perfectly fine for certain types of molding projects, we only use steel molds because steel molds have the following advantages over aluminum molds.

Make Sure Your Injection Molds are Properly Designed

In consideration of more complex injection molds, it is important that not only are they built to specification, but also that they are designed properly. With so many injection molders in the world, there are varying degrees of design competence. It takes a company with years of experience and knowledge to make sure the injection mold will work properly. For example, family molds (molds that create multiple parts in one shot) needs to be properly balanced. If a family mold isn’t made properly, you can get some parts in the mold that are short shot (not completed) or have flash. Flash can be especially detrimental as it may require extra manufacturing time to trim the part.

Process for Export Injection Mold

RCT MFG's rapid plastic injection molding quotation system and mold frame sharing technology allow us to simplify and shorten the plastic injection molding quotation and mold manufacturing process.

1. Load your 3D CAD file to get an injection mold quotation

2. After order confirmation, Jintai Mold begins the export mold order process

3. You will receive a 3D full mold design for review and approval

4. After design approval, Jintai Mold begins manufacturing the injection mold

5. Sample approval and trial production

6. Mold delivery

Export Tooling Ever Cheaper

Quality export tooling is ever cheaper with more professional team. Send your parts to see if it’s eligible.