Quality Control

As for the quality of goods, we have QC department to check. They will inspect the goods according to the working instruction that RD department issued and then record the results. QC people will also check on the points that sales note for customers' special requirements. Usually we follow RCT's AQL. However, if the customers have higher standard, we will follow theirs. For the products those we develop for customers, we keep the approved sample as golden sample for production reference. We also keep the sample from each shipment as sample archive. In case there's quality issue from production side or from customers, these samples will be very helpful to verify the issues.Though our inspection reports are written in Chinese, English version is available upon request.

Our quality control covers the entire project from project design and manufacturing to production and shipment.

IQC

Sample and production process inspection

Relevant testing and certification in accordance with customer standards.

Final inspection and test report and certification according to customer requirements

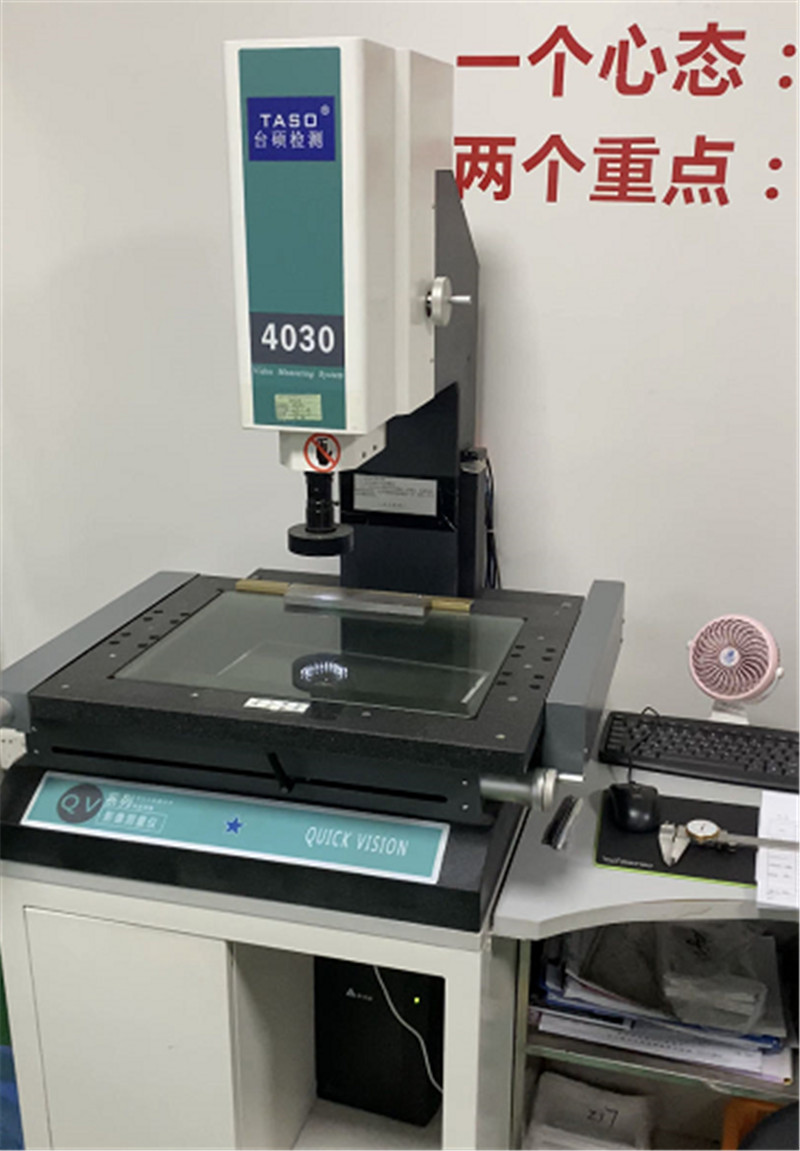

Testing Facilities

All of our inspection equipment in RCT, our quality engineers will send it to the authoritative company for verification according to ISO standards every year. We use the most effective quality inspection equipment, including CMM, 2D, projector, pin gauge, pass and stop gauge, micrometer, etc. to test the products of each project. Our quality team is constantly learning and discussing with customers the latest test standards to ensure higher quality requirements.

By understanding and implementing these elements in our quality management system, RCT is prepared to develop and manufacture the highest quality products for a global marketplace.

Regardless of your specification, print call-outs, or inspection criteria, RCT is ready to adapt its quality management system to your needs. Submit your project details today!