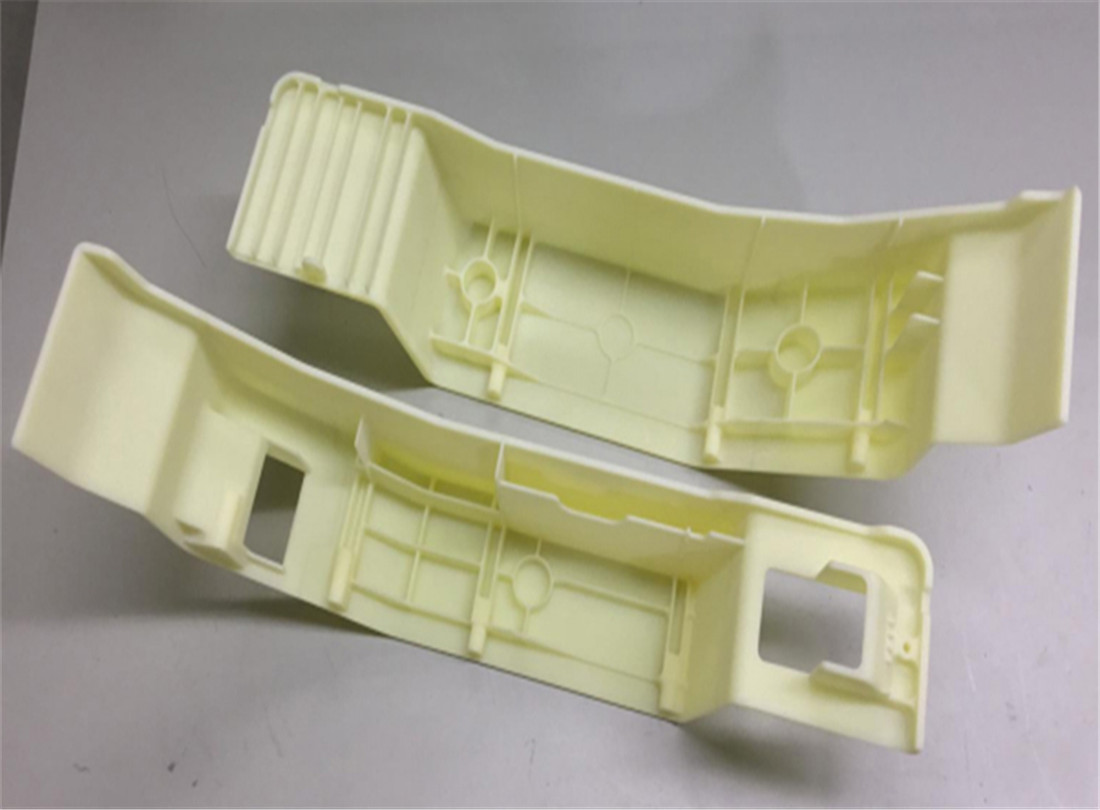

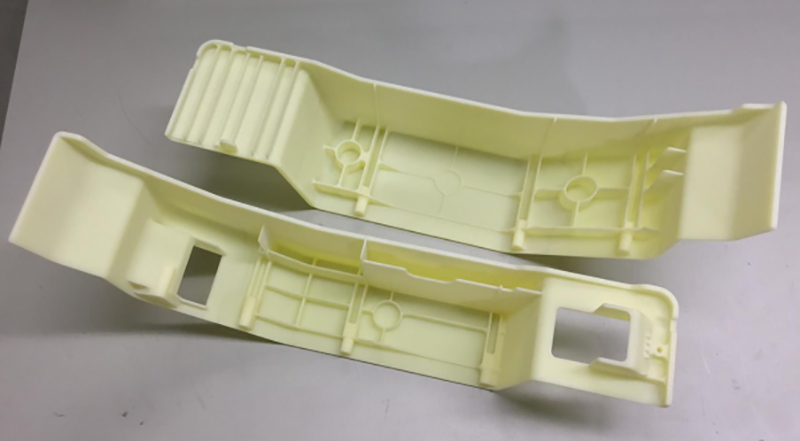

New RCT CNC Machining ABS plastic parts prototype for product development

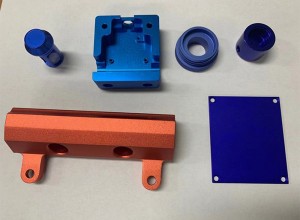

We offer a complete turnkey solution for creating prototype to final mass production based on your CAD designs. We not only make high-quality CNC prototypes but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.

In the new product design and development process, CNC machining ABS prototype is one of the most common prototypes, accounting for about 75% of the total amount of plastic prototype. This is because CNC machining ABS is a better engineering plastics, the strength can be very good to meet the needs of all kinds of prototype manufacturing. Such as test function, grinding, painting, plating and so on. Polished ABS material, then it is easier, and the surface is also guaranteed to be smooth. And the accuracy is also very good, generally if prototype needs to be painted, chrome plated, and silk screen, then the surface of the sticky is better, to polish very smooth.

CNC Machining ABS plastic parts prototype is also ideal for a variety of applications, including:

● Musical instruments

● Wheel covers

● Auto body parts

● Enclosures

● Molds with floating core

● Toys

● Protective headgear

Product Parameter for CNC Machining ABS plastic parts prototype

| Avaliable Production process | CNC machining, milling, drilling, sawing, turning, shearing, threading, |

| Avaliable material | Natural ABS, Black ABS, White ABS |

| Standard accuracy | ±0.1mm, special requirment can do ±0.05mm |

| Maximum part dimensions | 1900 x 900 x 750 mm |

| Surface treatment | smooth, painted, chrome plated, and silk screen..etc |

| MOQ | 1PCS |

| Leading time | shortest leading time is 3days from order to deliver |

| Inspection System | Technicians self-check & Engineer spot check during the production |

| Trained QA will make final inspection for each parts of each value to check the tolerance, funtion, assembly, appearance of surface finish by the assist of CMM,Projector,pin gauges, height gauge, radius gauge..etc. |

RCT MFG-Your Reliable Rapid Prototyping Companies

If you are looking for a rapid prototyping supplier in China, RCT MFG can be your best partner.

Normally,it is very hard to choose a new supplier to provide rapid prototyping service, can make a free rapid prototyping examples for you approve.

After get approved on the first rapid prototyping models,we will arrange other rapid prototyping parts.If you need rapid prototyping services,just drop us email.

During rapid prototyping manufacturing,Our technical and sales team will give update and feedback on the rapid prototyping production in time.You will know more details on your rapid prototyping processes.

We are on line always for you,just send the details info about your rapid prototyping projects.

Mold machining Machines