Shenzhen Die Casting Factory Custom A380 ADC12 Die Cast Part Aluminum Die Casting

Shenzhen Die Casting Factory Custom A380 ADC12 Die Cast Part Aluminum Die Casting

| Material | Aluminum alloy ADC12, ADC10, A360, A380, A356 Magnesium alloy AZ91D, AM60B Zinc alloy ZA3#,ZA5#,ZA8# |

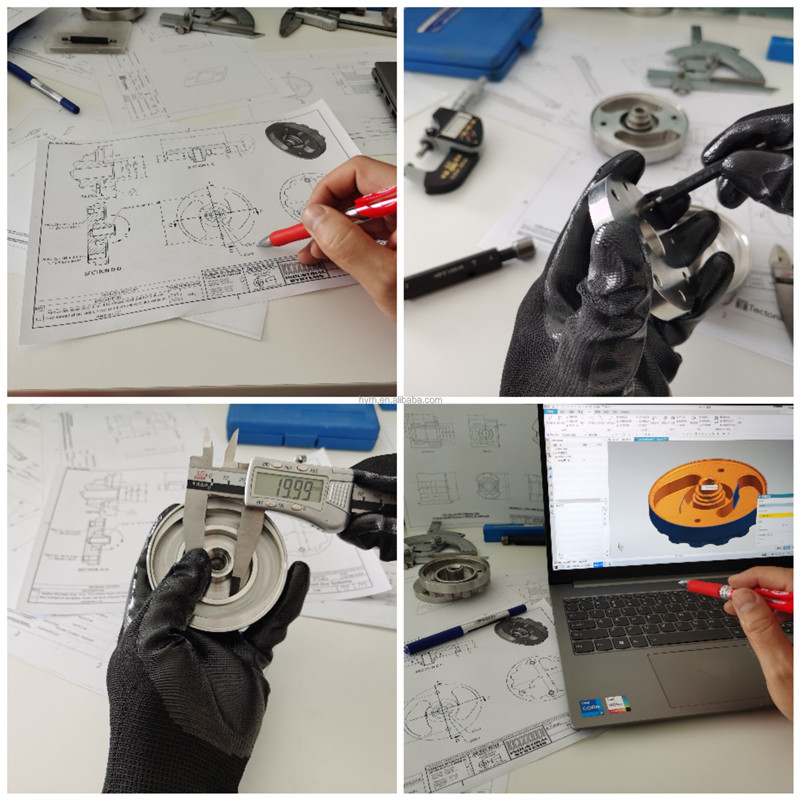

| Processing Craft | Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery |

| Machining | Turning, cutting, milling, grinding and drilling |

| Tolerance | As requirements |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance. 2.Third Party inspection available upon requirement |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Surface Treatment | Customer's Request: Powder coating/Plated/Anodize/Painting/Chrome plating/Sand blasting/Nickel plated/electroplate/Galvanized etc. |

| MOQ | 100pcs |

| Application | Electronic, telecommunication, heatsink, led light housing, pump housing, motor, furniture fittings, enclosure,compressor housing etc. |

What is Aluminum Die Casting?

Aluminum Die Casting is one of aluminum casting processes using die casting technique with aluminum alloys.

Since aluminum alloys are lightweight yet strong, they have become a popular choice for the die casting process. Through the process of aluminium die casting, it can be supplied in even more complex designs for a variety of applications.

The process is specially designed for complex aluminum parts production. Aluminum ingots are heated at high temperatures until they are entirely molten.

The aluminum is now liquid and is injected into a steel mold known as a casting mold (consists of 2 halves) under very high pressure. Once the molten aluminum solidifies in the mold, the solid cast aluminum parts form, which will be taken out from the mold.

The finished die cast aluminum parts usually requires no or minimal machining as it already has a smooth surface and good size accuracy. These steel molds can be used multiple times before wearing out. These features makes aluminum die casting ideal for high-volume production of aluminum parts.